Products

-

Household Products High Quality Plastic Injection Water Cup Mould

Plastic cup mold is a common daily necessities mold, there are a lot of mold, plastic cup mold, toothbrush cup mold, milk cup mold, mug mold, aviation cup mold, thermos cup mold and so on.model

With high-speed lathe processing, high precision, long life, cologne do plastic cup mold is more and more popular with the market, has rich experience in making plastic cup mold, through our company mold production process, not only can improve the life of the mold, but also can increase the plastic cup mold injection gloss of the surface of the product, at the same time will not appear fly / wool. -

16 / 24 / 48 Multi Cavity Bottle Cap Plastic Mould Pet Cap Cover Mold Flip Oil Bottle Mould Shampoo Bottle Milk Bottle Lid Household Packaging Mould

Taizhou Leiao Molding Co., Ltd. can produce the bottle cap mold within 64 cavity. According to the customer’s requirements, the hot flow channel or the cold flow channel structure can be selected. The hot flow channel of the bottle cap mold is designed with commonly used PE (polyene) free hot flow channel, the spring type electric heating ring and beryllium copper tube are heated, the hot flow nozzle is separately temperature controlled, the mold is produced under automatic conditions, without the frequent operation of employees, to reduce the labor force of workers. The key parts of the mold (core, cavity, slider) use German mirror anti-rust steel, and through the hot place (HRC 45), to ensure the service life and bottle quality of the mold. And the use of turning machining center processing, to ensure the processing quality of parts, to achieve mutual matching. Stable process, good use effect, can be comparable with the imported mold.

-

Custom Plastic Toilet Cover Mold-Toilet Lid Mold-Toilet Injection Mold- Plastic Mold Manufacturer in Shenzhen China

Make the toilet seat mold first mold of the steel to choose the right,In fact, to find the mold manufacturer, the intelligent toilet seat mold produced by Leiao company generally uses PP or ABS material,Mold surface finish is high, can not have flying edge burr.The steel uses Sweden one hundred S 136 or Japan Datong NAK 80 steel, the product assembly accuracy is very high, must use high speed milling machine or even 5 axis high speed milling processing.But the better the mold, the higher the maintenance requirements. Take the Japanese TOTO and Panasonic toilet mold produced by our Leiao mold as an example,intelligent toilet lid mold long-term use cannot leave the correct maintenance, proper mold compared to the no maintenance mold, can get longer service life, lower failure rate and higher product quality rate, this is a very effective method for injection molding products processing enterprises to reduce the cost, increase efficiency.

-

High Quality Custom 2 Cavities Plastic Clothes Hanger Mould on Sale

The hanger mold is an important factor in the hanger shape and quality. The hanger mold in the mold classification is almost all classified as the classification of injection mold, mainly related to the processing and use of the mold. Specifically, the heat melting material is injected from high pressure into the coat hanger mold cavity, after cooling and curing, to get the coat hanger forming product. The coat hanger injection molding process can be roughly divided into the following six stages: “mold-injection-pressure preservation-cooling-open mold-plastic coat hanger removal”, the above process is repeated, can be continuous production of products. The hanger mold can be made into multi-chamber mold, a mold can be out of multiple hanger products. Now in the process of mold processing, the production of one two and one four hanger mold majority.

-

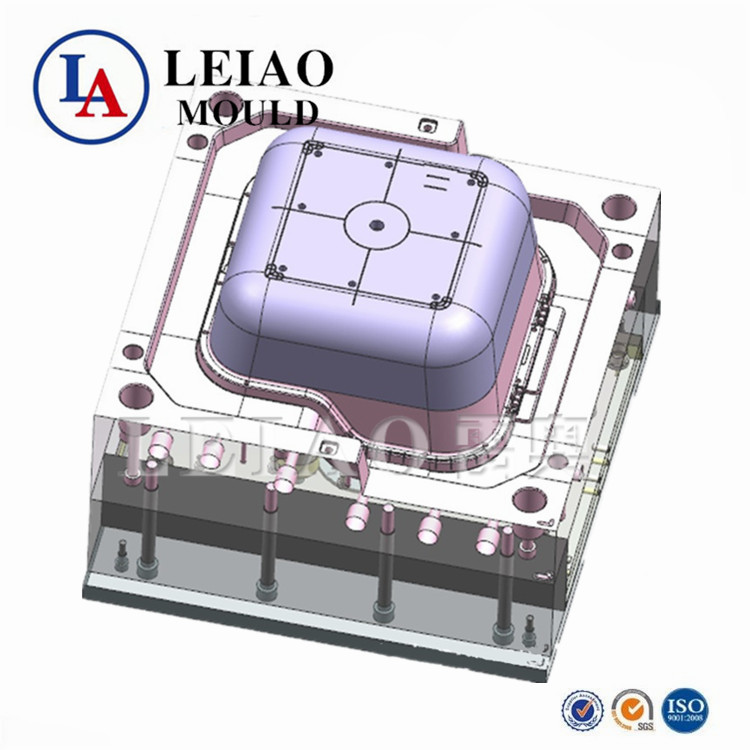

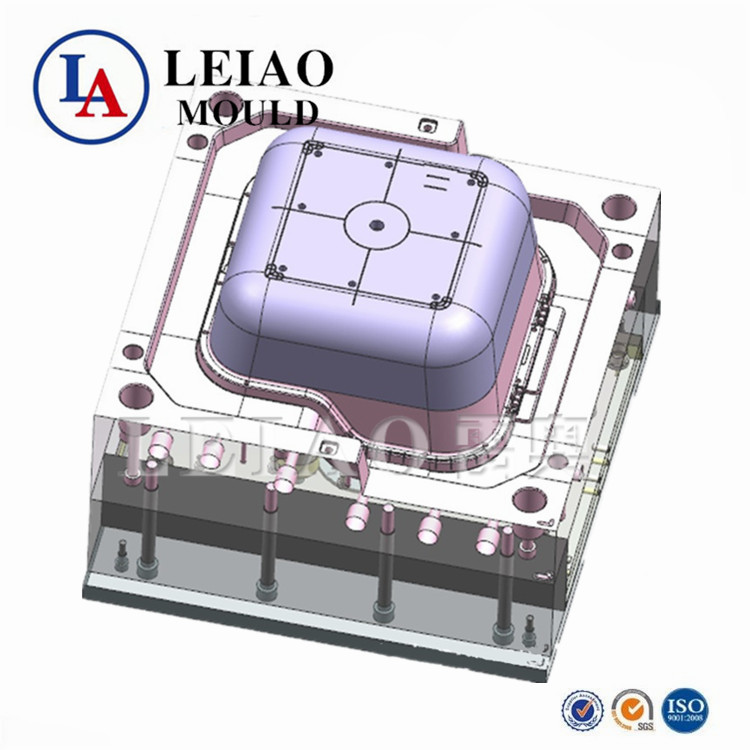

Plastic Semi Enclosed Cat Litter Box Pet Cleaning Large Training Pan Extra Clean up Product Plastic Space Sandbox Big Cats Toilet Mould

Over the years, Leiao has made hundreds of pairs of litter box models. The steel material of the cat litter box mold generally uses P20 or 718 steel material. Making cat litter box mold cooling system design is a more numerous lock work, namely to consider the cooling effect and cooling uniformity, and consider the influence of the overall structure of the mold the specific position and size of the cooling system in mold design began to analyze these a series of problems, mold in the way of circulating water inside the mold flow, reduce the cooling time of injection molding, improve the production efficiency of products, greatly reduce the production cost.

-

High Quality Car door panel mold

The injection molding part of the automobile door plate is located on the inside of the automobile door, installed in the front and back of the door, which is an important part of the automobile interior parts. The automobile door panel is an exterior part, and the welding line is not allowed. When injection molding, the fusion line needs to be driven to the non-appearance area or eliminate the fusion line. By using the 3-point sequential needle valve hot flow channel system, the opening and closing of the 3 hot nozzle heads are controlled by the oil cylinder or cylinder, so as to achieve the injection molding effect without the fusion line. The selection of the glue inlet position is mainly determined by the mold flow analysis, and the type of the glue inlet is mainly determined by the large water outlet and diving. But one thing needs to note:the glue position is in the non-appearance position or after the door panel assembly is not easy to see the position, such as the bottom of the door plate.

-

240L Plastic Pedal Rubbish Bin Injection Mold Ash-Bin Body Mould

There are so many kinds of trash cans, For example, trash cans used in sanitation and sanitation systems, large in size, The 240L trash can has reinforced turning edge and bucket cover fixing holes, Garbage can plastic piece is a end cover part, With relatively thin walls, Easy to pull the deformation, Easy top deformation, Generally using plastic mold integrated injection molding molding, But trash can parts are often because after forming, cooling shrinkage, Ctightly around the core, In the process of moulmolding, Due to the large force area of the lateral walls, Make the huge friction between the product and the surface of the core exist, When the top rod is pushed out of the product, It is difficult to emerge, Thimble bending, Thimble tops the product out of the white dot defect settings to top the product through.

-

OEM Car Interior Accessories Injection Mold Company Plastic Automobile Dashboard Mould

The instrument panel is a very unique part of the car, integrating safety, functionality, comfort and decoration. The main die drawing direction of the instrument panel is determined according to the outer surface of the instrument panel and the air outlet position. It is generally between 20 degrees and 30 degrees, and the die drawing direction of the secondary instrument panel is vertical; the direction of the outer surface of the instrument panel is at least 7, which shall be determined on the depth of the surface skin pattern of the instrument panel. The drawing angle of the invisible area should not be less than 3. If less than 3, the surface of the parts may produce other marks, because the use of slider will first affect the appearance of the parts, and then affect the life of the mold, and the mold cost will increase accordingly.

-

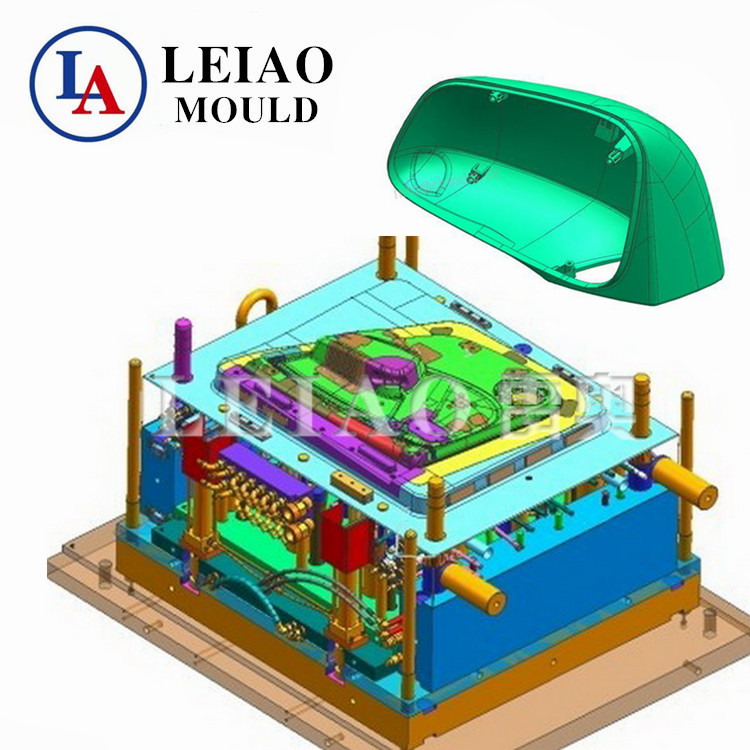

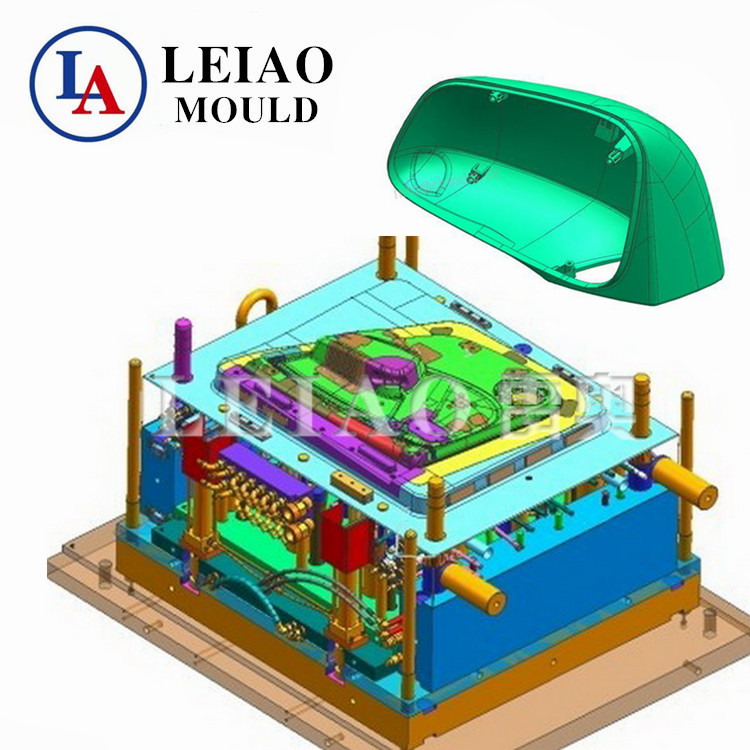

Factory Price Customized Auto Parts Rearview Mirror Mold of Plastic Auto Parts Mold

During the injection molding process, the cavity of the mirror shell mold will be affected by high pressure, so the mirror shell mold cavity should have sufficient strength and stiffness. Insufficient strength will lead to plastic deformation and even cracking; insufficient stiffness will lead to elastic deformation, leading to the outward expansion of the type cavity and the overflow gap. Due to the large size of the mold cavity of the automobile rearview mirror shell, the internal stress of the cavity often exceeds the allowable stress before the large elastic deformation, so the strength of the cavity should be checked.

-

Plastic Moulding Manufacture Customize Safety Helmet Mould OEM Custom Parts Mold

Helmets are divided into full helmets, 3/4 helmets, half helmets, assembled helmets, etc. The main material of the helmet is ABS resin material, which is an engineering plastic with strong impact ability and good dimensional stability.

-

Injection Plastic Car Bumper Bracket Mould

Product Description Model NO. LA23-002 Application Auto parts mold Runner Hot Runner/Cold Runner Design Software UG Installation Fixed Certification TS16949, ISO Trademark LA Customized Customized After-sales Service 1year Transport Package Wooden Case Specification HS Code 8480719090 Origin China, Zhejiang, Taizhou Production Capacity 650 Set/Year Mold Traits There are several areas to note when designing and ... -

Injection Car Lamp Plastic Cover Auto Lamp Mould

The automobile lamp mold includes headlight mold and taillight lens mold, etc. The previous CAE analysis is used to predict the molding pressure, reduce the actual molding pressure and reduce the adhesive front mold; for the automobile lamp headlight BEZEL, through the previous CAE analysis, the automobile lamp is very high, so the mold needs to be polished to the mirror.