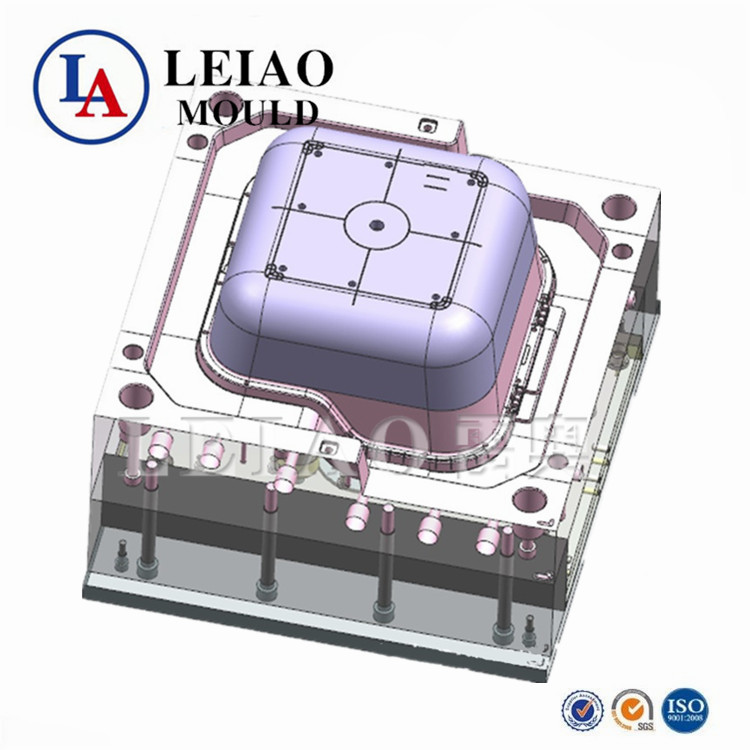

240L Plastic Pedal Rubbish Bin Injection Mold Ash-Bin Body Mould

Product Description

| Model NO. | LA22-111 | Application | Furniture, Commodity, Home Use, Transportation |

| Runner | Hot Runner/Cold Runner | Design Software | UG |

| Installation | Fixed | Certification | TS16949, ISO |

| Trademark | LA | Customized | Customized |

| After-sales Service | 1year | Transport Package | Wooden Case |

| Specification | 1.5L/5L | HS Code | 8480719090 |

| Origin | China, Zhejiang, Taizhou | Production Capacity | 650 Set/Year |

Therefore, in the mold design, the mold opening speed can not be too fast, and we need to solve the difficult technical problems in the production process. At present, although there are related mold production injection molding, but in actual production, due to the size of the trash can, the corresponding mold volume is large, therefore, trash can mold structure is very complex, and the traditional mold of the limit block with overall cutting, polishing, processing difficulty, material waste, lead to production cost is very high, and size precision is difficult to control, thus affecting the mechanical strength of the product, easy to cause product quality defects.

Leiao company after a long period of exploration, proposed a variety of solutions. With the development of high technology content, for the mold material, quality, variety and performance are put forward update requirements, large long life mold market is more and more favored by customers, our company in years of manufacturing experience, summed up the unique processing process, for different mold cost, and greatly enhance the competitiveness of the products in the market.

Standing from the customer's point of view, there is no problem. Standing in the customer's point of view to think of benefits, we will also get benefits from it. What we can do and must do is to create a good mold for customers to save worry and money.

Mold Traits

The 240L trash can is made of plastic HDPE (low pressure high density polyethylene) raw materials and other fortifiers (such as anti-aging, etc.). The vacuum suction machine draws the raw materials into the channel of the large injection molding machine. After the high temperature raw material, it is accumulated into the mold cavity by the strong high pressure of the injection molding machine, and formed at one time after cooling.

1

Injection molding, acid resistance, alkali resistance and corrosion resistance.

2

Integrated plastic structure, tough and durable, can withstand all kinds of external forces.

Why choose Leiao Mould for the production of household Mould?

Leiao Mould is a one reliable and professional high quality custom plastic mould manufacturer engaged in mould design,manufacturing & produce a variety of plastic injection moulds.We have a mature team of highly skilled designers, Engineers, Project Managers and Fabrication Technicians that ensure strictly control all of the project success.

We Specialize in manufacturing all kinds of plastic moulds,such as plastic crate moulds, Car parts mold,plastic pallet moulds,plastic chair moulds, plastic household moulds, plastic Home-appliance moulds, Plastic industries moulds,tableware moulds,etc.