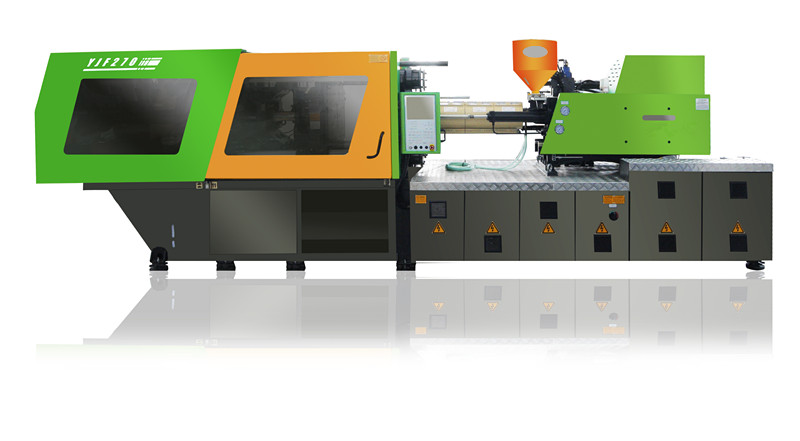

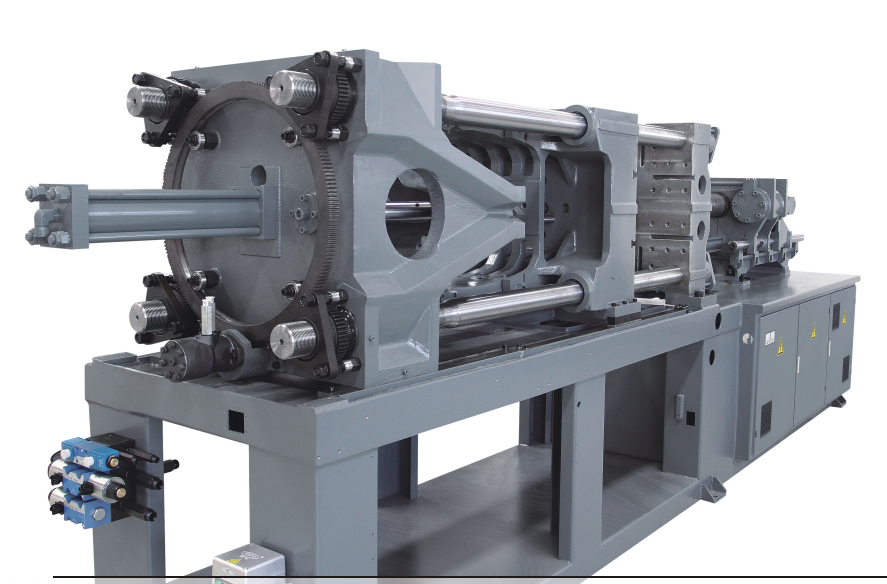

Injection Molding Machine For PET Preforms

Product Parameters

| Plastic Processed | PET | Condition | New |

| Style | Horizontal | Distance between Tie Bars(Width)(mm) | 545mm |

| Distance between Tie Bars(Height)(mm) | 545mm | Mold Height(mm) | 180 - 560 mm |

| Ejector Stroke(mm) | 160 mm | Ejector Force(kN) | 90 kN |

| Theoretical Shot Volume(cm³) | 778 cm³ | Injection Rate (g/s) | 420 g/s |

| Machine Type | Hybrid | Injection Weight (g) | 1010 g |

| Screw Speed (rpm) | 50 - 157 rpm | Screw diameter (mm) | 60 mm |

| Screw L/D Ratio | 25 | Distance between Tie Bars | 545x545 mm |

| Weight (KG) | 7500 | Type | Preform Injection |

| Place of Origin | China | Open Stroke(mm) | 520mm |

| Model Number | ZX220-PET | Brand Name | Pairui |

| Power (kW) | 17.5 kW | Warranty | 1Year |

| Key Selling Points | Flexible Manufacturing | Applicable Industries | Food & Beverage Factory |

| Showroom Location | None | Machinery Test Report | Provided |

| Video outgoing-inspection | Provided | Warranty of core components | 1Year |

| Product name | Injection Molding Machine | Machine Dimensions | 5.6m x 1.3m x 2.0m |

| Marketing Type | New Product 2020 | Certification | CE |

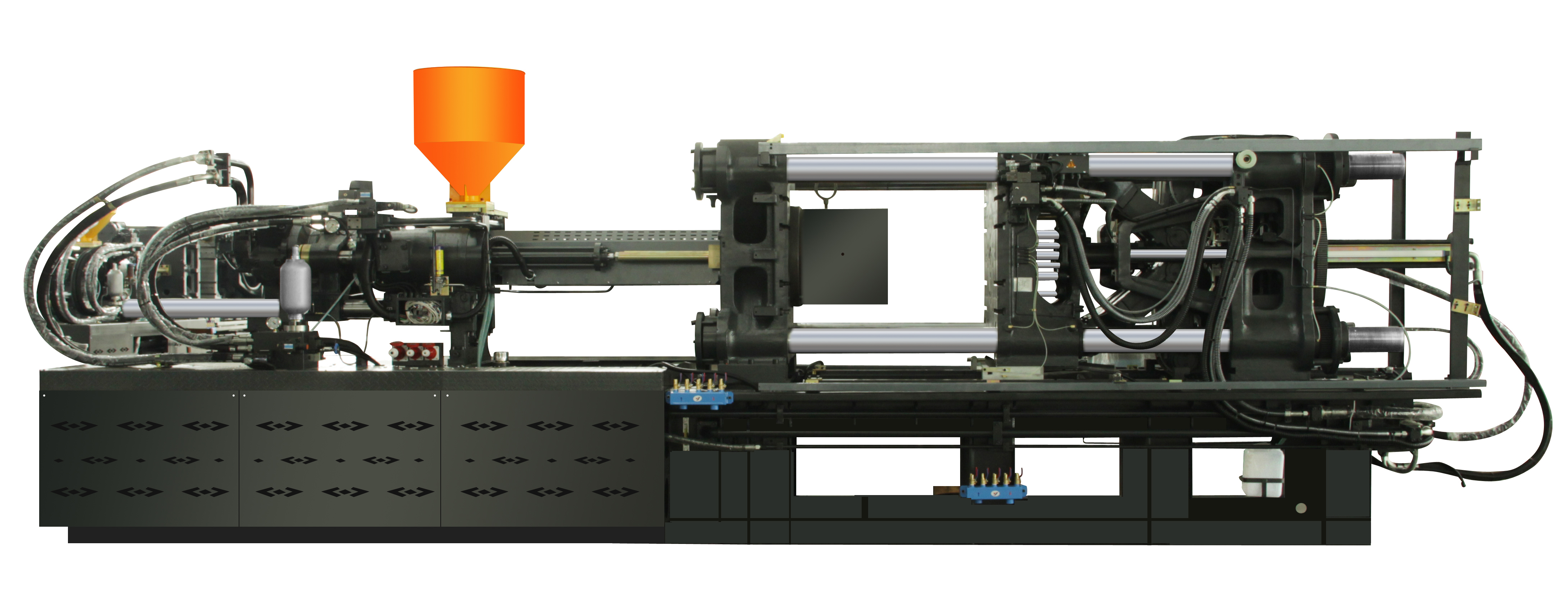

Injection Molding Machine

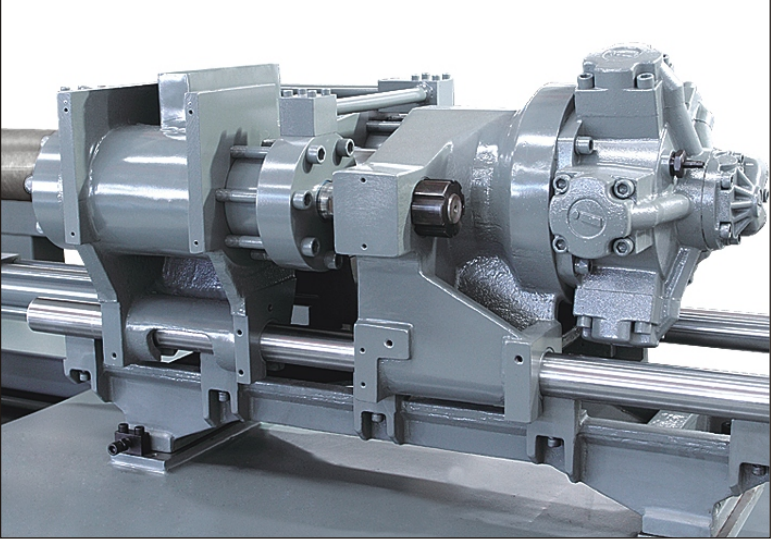

- The PET special screw is used to significantly increase the melt speed and Injection volume, and reduce the plasticizing temperature With AA value, effectively improve the shrinkage of the preform and increase transparency.

- A full set of PET bottle production technology and equipment can be provided, including : injection molding machine, blow molding machine, mold Tools and other related equipment.

Product Paramenters

| Measurement | Item | ||

| Injection Unit Data | ZX 220- PET | ||

| Screw diameter | mm | 60 | 70 |

| Screw L/D ratio | - | 25 | 25 |

| Screw stroke | mm | 275 | |

| Theoretical shot volume | cm3 | 778 | 1059 |

| Shot weight PET | g | 1010 | 1375 |

| Injection pressure | Mpa | 142 | 104 |

| Max. screw speed | rpm | 157 | 113 |

| Injection piston speed | g/s | 420 | 580 |

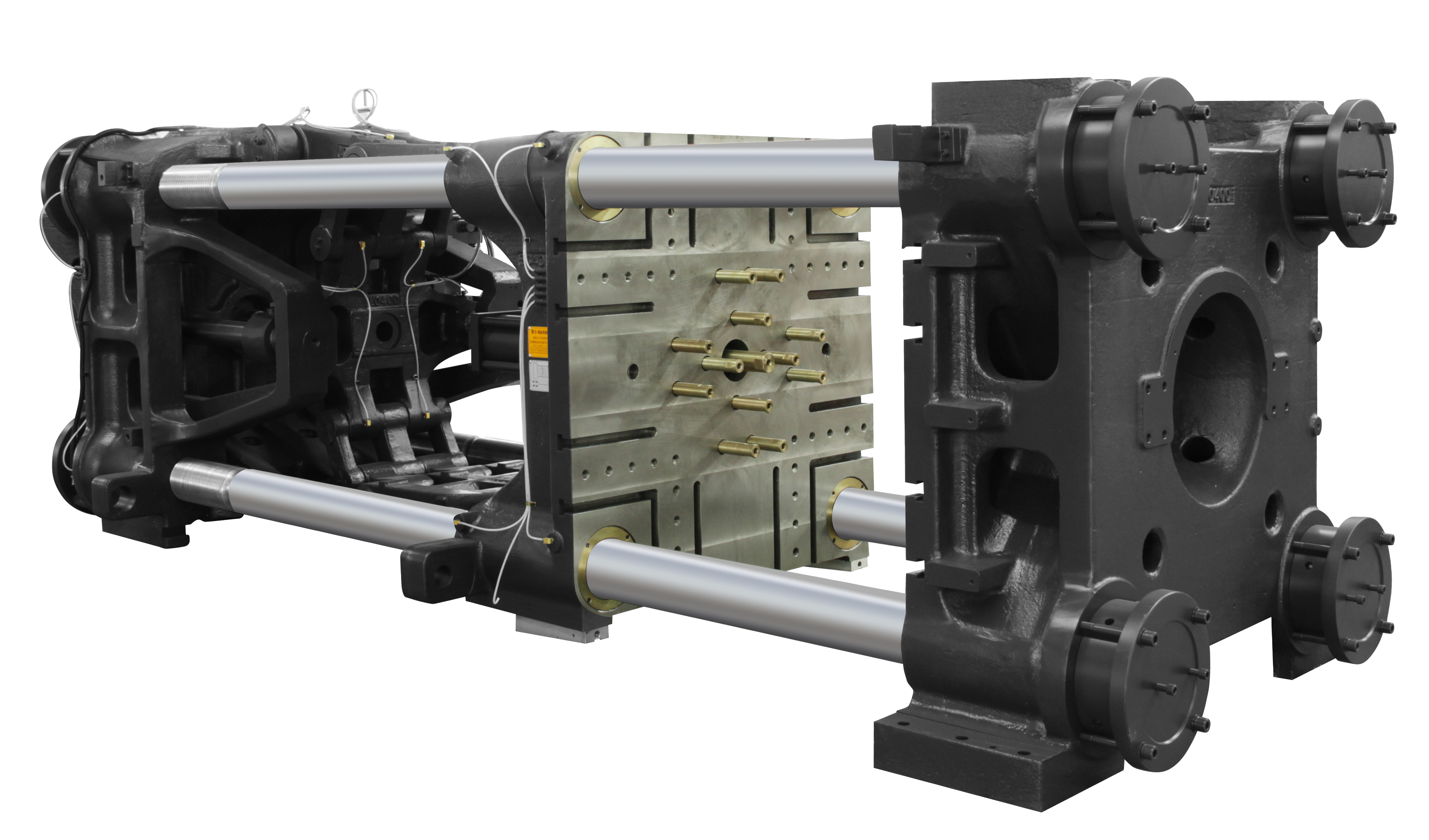

| Clamping Unit | |||

| Clamping force | KN | 2200 | |

| Tie-bar distance (HxV) | mm | 545*545 | |

| Opening Stroke max | mm | 520 | |

| Mold height min | mm | 180 | |

| Mold height max | mm | 560 | |

| Ejector stoke | mm | 160 | |

| Ejector force | KN | 90 | |

| Number of ejector bar | KN | 7 | |

| Other | |||

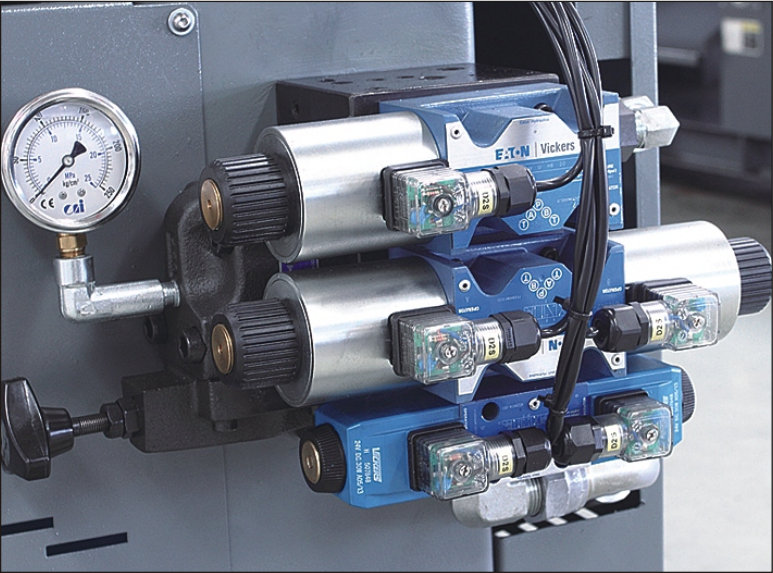

| Sys. Pressure | Mpa | 17.5 | |

| Pump motor | KW | 30 | |

| Electric heating power | KW | 20.6 | 27 |

| Machine dimensions | m | 5.6* 1.3 *2.0 | |

| Machine weight | Ton | 7.5 | |

Before Cutting

After Cutting

Production Plant

Write your message here and send it to us